Reflex Gauge Glass

Reflex Gauge Glass For Boiler-Made in Aluminosilicate and Borosilicate Glass

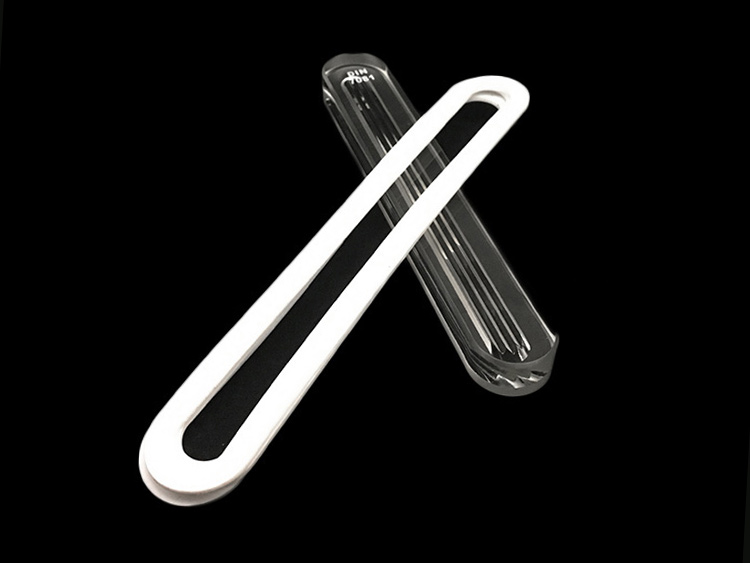

Reflex gauge glass, also named reflex sight glass, reflex level gauge glass, boiler glass and reflex level gauge.

Aohong Special Glass Manufacturing Co., Ltd. is a modern, high-tech enterprise with over two decades of experience in producing and selling reflex level gauge products. As a top-notch Reflex Gauge Glass manufacturer in China, Aohong guarantees the production of quality Reflex Gauge Glass tailored to your needs. We ensure a friendly and responsible service experience, both pre and post-cooperation. Customization is accepted.

Reflex gauge glass commonly known as sight glass or reflex sight glass, the Reflex Gauge Glass is a meticulously crafted product from Aohong Special Glass Manufacturing Co., Ltd. Its manufacturing process involves fine grinding, polishing, and tempering to ensure that it achieves both robustness and transparency. This intricate process allows the Reflex Gauge Glass to resist the corrosive effects of the liquids found within boilers, ensuring longevity and optimal performance.

Reflex Water Level Gauge Glass

Boiler Level Gauge Glass

Borosilicate Reflex Glass

1, Materials

Borosilicate Glass and Aluminosilicate Glass

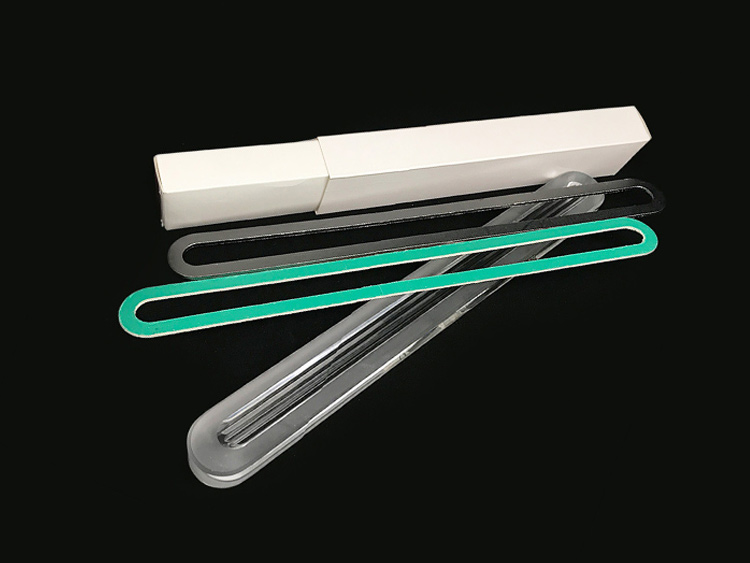

Our Reflex Gauge Glass is primarily produced using two types of glass materials: borosilicate glass and aluminosilicate glass. Borosilicate glass is highly resistant to thermal shock, making it ideal for applications with rapid temperature fluctuations. It also offers excellent chemical resistance. Aluminosilicate glass, on the other hand, provides a superior surface quality and increased hardness, making it more resistant to scratching and wear. Each material has its unique properties, and the choice depends on the specific requirements of the application.

2, Features

One distinguishing feature of the Reflex Gauge Glass is its grooves. These grooves serve to enhance the refraction and reflection of light, improving the visibility of liquid levels. The result is a clearer, more accurate reading for operators, enabling better control and monitoring of liquid levels in various industrial applications.

Packaging

After Sales Warranty

3. Surface Treatment

The surface of our Reflex Gauge Glass undergoes a thorough polishing process. This not only enhances the aesthetic appeal of the glass but also improves its functional performance. Polishing eliminates any surface irregularities that might impact visibility or compromise the integrity of the glass. It also aids in resisting chemical interactions and abrasive wear, thus extending the lifespan of the product. This careful attention to detail ensures that our Reflex Gauge Glass provides the optimal balance between durability, performance, and aesthetic appeal.

4. Manufacturing Process

Our Reflex Gauge Glass is produced in accordance with DIN7081 standards. The thermal toughening process increases the tensile bending strength of the glass by at least a factor of two. This is an essential step that ensures the gauge glass’s safety and reliability, complying with the high safety demands stipulated by DIN 7081. It guarantees a product capable of withstanding high pressures and temperatures while maintaining its integrity, making it a trustworthy choice for any industrial applications.

5. Applications

Our Reflex Gauge Glass finds wide-ranging applications across numerous sectors, delivering optimal solutions for the monitoring of liquid levels. Reflex Gauge Glass is a primary component of reflex level gauges, which are widely used to measure liquid levels in tanks and vessels.

1) Industrial Boiler Level Gauges: Due to its robustness and high resistance to extreme conditions, the Reflex Gauge Glass is commonly used in industrial boiler level gauges. It provides an accurate and clear indication of the water level, ensuring efficient boiler operation and safety.

2) Saturated Steam Applications: For applications involving up to 35 bar of saturated steam in boilers, Reflex Gauge Glass offers an optimal solution. It can withstand the high pressure and temperature conditions, delivering reliable performance and longevity.

3) Corrosion Resistance: With its high resistance to corrosion, Reflex Gauge Glass can be used in scenarios involving corrosive liquids. Its durability and clear indication make it ideal for such demanding environments.

4) Broad Media Compatibility: Apart from steam at service conditions, Reflex Gauge Glass is compatible with all other media. This makes it a versatile choice for different industries.

5) High Pressure and High-Temperature Applications: Reflex Gauge Glass can withstand pressures up to 400 bar and temperatures up to 400 °C, demonstrating its strength and durability. It remains reliable and offers clear visibility even under these extreme conditions.

Sinopro Service Pledge

- Quality Product

- Order On-Line Tracking

- Timely Delivery

Sinopro Service Pledge

- Credit Rating

- Credit Services

- Credit Purchasing

Sinopro Service Pledge

- 427+ Categories

- 2800+ Suppliers

- 200+ Brands

Post Your Inquiry

Post Your Inquiry

.jpg)

.jpg)